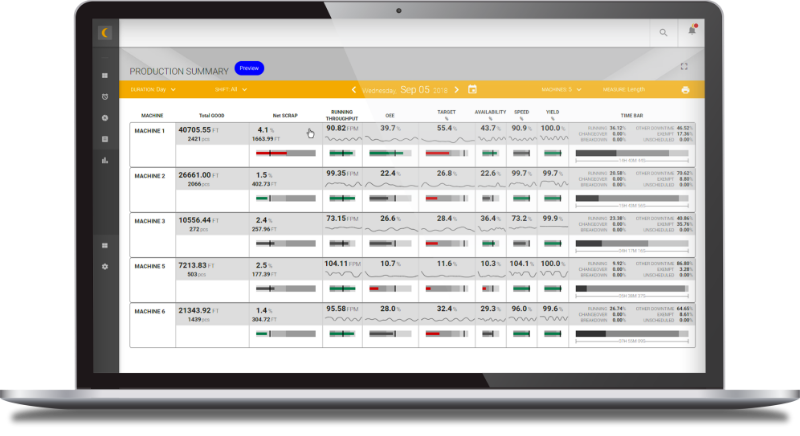

At AMS Controls, we didn’t create our software just for the sake of creating software. Eclipse Pro Production Management Software has a powerful purpose. It was born out of the manufacturing challenges our customers have faced for the last thirty years. Each was solved through Eclipse Pro and the power of data that makes the unknown, known. It’s another way AMS provides you with control beyond the controller.

With the features in Eclipse Pro, you can achieve optimal control of order and part data, scheduling, coil selection, machine setup, and data collection. These are mistake-proofing tools that give you more than just a competitive advantage during the manufacturing process. It makes every operator your best operator. Because if you’re not making mistakes you’re making more money. A lot more.

We’ve seen and heard it all. And chances are, Eclipse Pro Production Management Software has already solved it. Contact us to learn more.