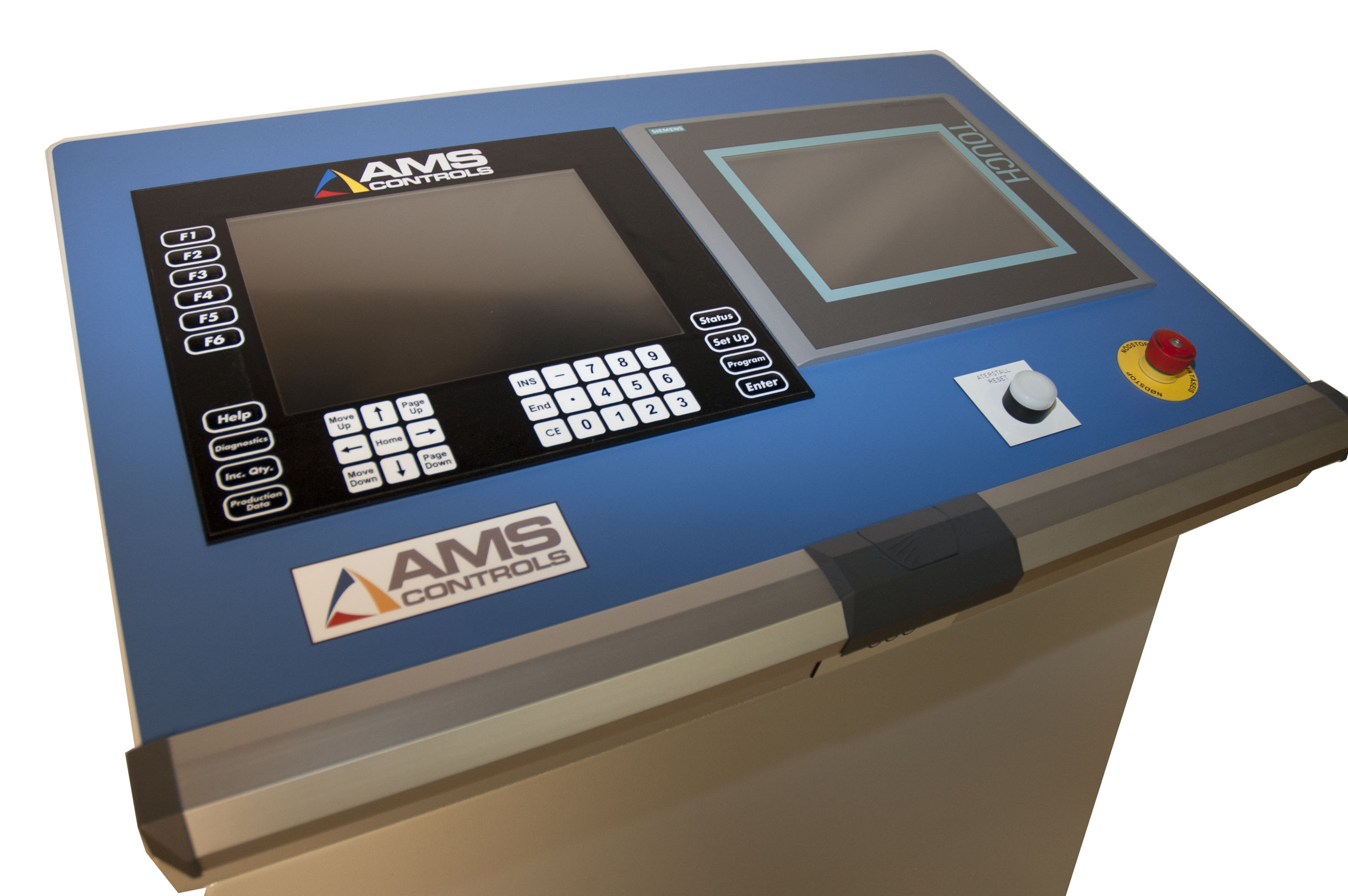

XL200 Series Options

There are several different XL200 series controller models available from AMS Controls. Each model may be configured to operate in different modes depending on the options available. The basic controller model number indicates the base model of the controller without options (for example, XL200CL indicates a base controller for a closed-loop system).

Additional optional features will change the controller model number by adding the associated letter or letters to the end of the basic model number. For example, an XL200CLB is a closed-loop controller with optional Bundle Tag printing.