FoldGuard for Pathfinder

Folding Machine Safety and Guarding System

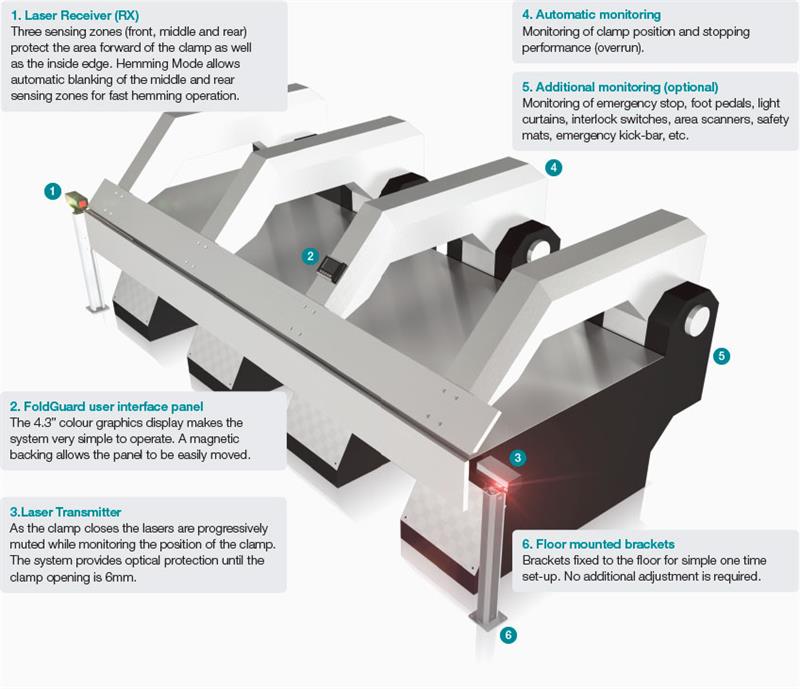

The FoldGuard for Pathfinder safety and guarding system was developed by Lazer Safe specifically for C-frame style folding machines. It provides a complete safety solution including optical guarding of the clamping operation, clamp speed, and overrun monitoring and management of additional machine safety components.

AMS Controls is the exclusive provider of the FoldGuard system. It is available as part of our Pathfinder Folding Machine Controls system for new or retrofit applications. It can also be installed as a stand-alone safety system for folding machines without Pathfinder.