Improving Production Capacity with Computer Integrated Manufacturing (CIM)

Now that the manufacturing market is picking back up, the idea of developing production capacity is probably on the minds of many manufacturers. Certainly, when demand is strong, companies have a big incentive to add equipment or expand facilities in order to keep up. But even when demand is slowly increasing, manufacturers need to find a way to keep costs low and efficiently increase production capacity.

Having the ability to quickly turn around accurate orders can mean the difference between success and failure in this improving economy. The ability to carefully control labor costs is also an important consideration. Companies who have streamlined their production data flow through Computer Integrated Manufacturing (CIM) will have lower downtime and will be able to promise (and deliver) their goods faster.

How can CIM help?

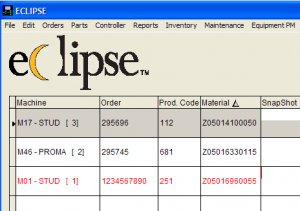

A CIM system such as Eclipse Production Management Software can directly improve production capacity by eliminating the downtime otherwise needed for data entry of orders and manual recording of production and coil usage. We have seen cases where the machine operator wastes sometimes as much as 100 minutes in a shift manually programming order data and punch patterns. Not surprisingly, these are always the first machines that need overtime or additional shifts when demand increases.

In an integrated system, no time is wasted entering cut-lists, programming punch patterns, changing messages on part printers, configuring automated stacking equipment, updating completion reports or recording footages for coil consumption. While each of these tasks may only require a few seconds or minutes at a time, the extra production capacity gained by eliminating them can add up quickly.

The information provided by CIM can also be a big help in reducing downtime and increasing production. In order to make improvements, managers need information about the best place to direct their time and budgets. The following are typical questions:

- How are my operators performing? Who is the best and why? For operators that are lagging behind, what areas should we focus on?

- How efficient are our production schedules? Are we doing needless changeovers because of poor planning?

- Outside of the roll formers, how is the rest of our system performing? Are the mills ever delayed waiting for coils to be delivered or for bundles to be taken away?

- What are the most common unplanned maintenance downtimes? How often do they occur and for how long? Do they ever impact our delivery promises?

- What are the bottlenecks on the machines that are currently limiting throughput? If we could eliminate these constraints, how much extra production would be gained?

- How can we justify upgrades to existing equipment?

- When buying new machinery, what features or specifications are the best fit for our production needs? Can we justify higher levels of automation?

- Are our machines capable of producing at the specified tolerances? If not, we will waste a lot of time and material.

Example

The purpose of this example is to show how seemingly small improvements can add up to dramatic increases in capacity.

The example is based on a fairly typical machine which processes an average of 15 orders during shift 1. Each order typically has around 10 items. The machine has an ink-jet printer that is marking each part. Some of the information in the print message must be changed per order.

Data Entry Savings

Before implementing Eclipse, the operator spent an average of 9.7 seconds per line item for data entry at the machine controller. He also spent around 45 seconds changing information on the ink-jet printer per order. With Eclipse in place, all job data was downloaded to the XL200 Series controller. Since the XL200 was integrated with the printer, the operator no longer had to waste time (and risk mistakes) with print message data entry. The resulting downtime reduction can be calculated as follows:

Item data entry: 15 orders * 10 items * 9.7 sec. = 1455 sec. = 24.25 minutes

Printer data entry: 15 orders * 45 sec. = 675 sec. = 11.25 minutes

Total downtime directly saved by integration (per shift): 35.5 minutes

Coil Change Procedure Savings

By reviewing the Pareto chart in Eclipse’s downtime summary report, management was able to see that coil changes were responsible for more than a third of the total downtime. There were 7 hours (420 minutes) of scheduled production time per shift (after subtracting break times). The machine ran for an average of 118 minutes (28%) leaving 302 minutes of downtime. There was an average of 12 coil changes per shift.

Management also noticed that while the average coil change time was 9.3 minutes, one operator was able to consistently perform a coil change in 7.8 minutes or less. By simple observation, it became apparent that this operator was faster because of the way he prepared for the changeover (while the machine was still running). By adopting this technique as a standard, the company was able to get the average coil change time down to 8.1 minutes. This lead to another reduction in wasted downtime:

Previous coil change time per shift: 12 changes * 9.3 minutes = 111.6 minutes

Improved coil change time per shift: 12 changes * 8.1 minutes = 97.2 minutes

Downtime saved by improved coil change process (per shift): 14.4 minutes

Uncoiler Upgrade Savings

Even with this reduction in coil change times, it was still the largest downtime cause and was a natural target for capital budgeting. To go from a single-mandrel un-coiler to a dual unit would have a big impact on the changeover time since it would shift much of the process from internal time (requiring the machine to be stopped) to external time (while the machine is running). For a change, the operator only needs to cut off the material before the roll former and rewind, then spin the un-coiler around and thread-up the new coil. The old coil can then be removed and the next one staged while the machine is running. This should reduce the average coil change time to 5 minutes or less (additional 37.2 minute downtime reduction).

Previous coil change time per shift: 12 changes * 8.1 minutes = 97.2 minutes

Improved coil change time per shift: 12 changes * 5.0 minutes = 60.0 minutes

Downtime saved by improved coil change process (per shift): 37.2 minutes

The Need for Speed?

Although the improvements only shaved off a few minutes here and there, the total reduction in wasted time was dramatic:

Downtime directly saved by integration (per shift): 35.5 minutes

Downtime saved by improved coil change process (per shift): 14.4 minutes

Downtime saved by improved coil change process (per shift): 37.2 minutes

Total Downtime reduction (per shift): 87.1 minutes

How good is 87 minutes of reduced downtime? A good analogy is a driving trip: the distance traveled is like production output, speed is speed and pit stops are downtime. Consider two cars leaving at the same time and driving to the same destination far away. The first car has two adults and the second has one adult and three small children. If both cars are to arrive at the destination at the same time, how much faster must the second car drive to make up for the frequent and sometimes lengthy toilet breaks? Thankfully, there are speed limits in most parts of the world. With roll forming, the exact same calculation can be made and equipment cost serves as the speed limit.

After the improvements, the machine is able to go from 118 minutes to 205 minutes of production time. A machine running 215 fpm (66 mpm) would need to be upgraded to run at 370 fpm (113 mpm) to get the same increase in output. As with the driving example, while this machine speed increase may be possible, it is probably not a practical solution.

Financial Considerations

What does 87 minutes of additional production capacity look like in financial terms? As with many things, the answer depends on the circumstances. If you are unable to keep up with your customer’s demand for your products, 87 minutes a shift equates to a large sack of money! Consider the following example:

Average machine speed: 215 fpm (66 mpm)

Increased run time/shift: 87 minutes

Additional product/shift: 18,705 feet (5701 m)

Lineal gross margin: $0.60/foot ($1.96/m)

Incremental revenue/shift $11,223

This is an extreme case. Customers who have this kind of demand quickly attract competitors and the situation would probably not continue. If you are able to win jobs because of your increased responsiveness, however, the additional margin from this work should be considered. Aside from this margin, increased production capacity should allow you to delay or eliminate the need to go to overtime or additional shifts.

Conclusions

If you are not already using a CIM system such as Eclipse, it is well worth considering. For a relatively small investment you can directly improve your production capacity, responsiveness to customer requests, and competitive position in your market.

The information provided by Eclipse helps to amplify the effects of your company’s management and improvement projects. It also gives great insights into what is really happening on your plant floor. Now is the time to position your company to succeed.