Roll Forming and Industry 4.0

Cheerleading the Continuing Integration of Manufacturing

How did we get to Industry 4.0?

Around 2011, the German Industry-Science Research Alliance (Forschungsunion Wirtschaft-Wissenschaft) proposed that the German government should fund a research program that would study developments in industrial technology with the goal of maintaining the country’s long-term competitiveness. This fit within Germany’s High-Tech Strategy 2020 project and the research program was funded with a budget of €400 million. The working group that was created was composed of 16 companies, 10 institutes, 2 trade unions and 4 trade associations. It was coordinated by Dr. Siegfried Dais of Bosch and Prof. Dr. Henning Kagermann of acatech (German National Academy of Science and Engineering).

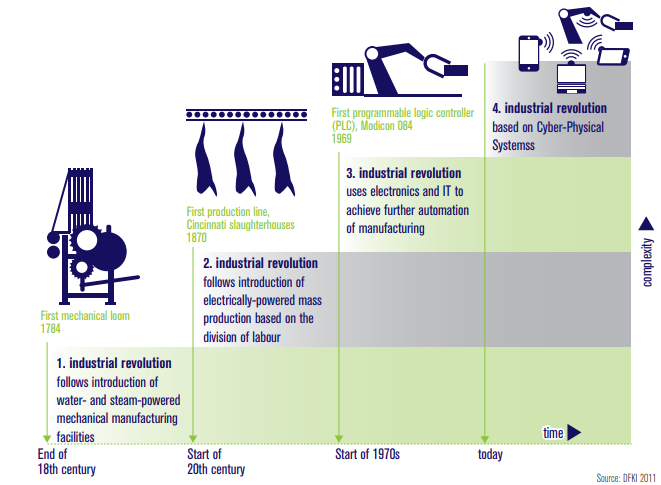

The name “Industry 4.0” comes from the idea that we are at the beginnings of a 4th major industrial revolution:

As most politicians holding office have an aversion to the word “revolution”, the name was shortened to “Industry 4.0.”

The vision and goals of the program are quite ambitious:

- Individualization (batch sizes of 1) at mass production prices will become a reality

- Manufacturing will be highly flexible, extremely productive (up to +50%), will use fewer resources (up to -50%) and will be compatible with an urban environment

- Dynamic design of business and engineering processes

- Work-life balance taking account of availability of individual workers

- Older employees supported by smart assistance systems

- Existing infrastructure can be upgraded gradually

- A high-wage economy that is still competitive!

The group’s final report was published in 2013.

What is Industry 4.0?

In many ways, the 82-page final report serves as a high-level “to-do list” for industry, academia and regulators. While it does give overall direction, it understandably leaves the implementation details to others.

Main Characteristics

There are three main characteristics of Industry 4.0:

- Horizontal integration through value networks

- End-to-end digital integration of engineering across the entire value chain

- Vertical integration and networked manufacturing systems

A key requirement for each of these is the need for a real-time continuous and automatic exchange of data throughout all systems.

Horizontal integration through value networks

This essentially covers how various players in a value chain cooperate and interface with each other.

End-to-end digital integration of engineering

This involves the use of digital models from product concept development through manufacturing system engineering, production and service.

Vertical integration and networked manufacturing systems

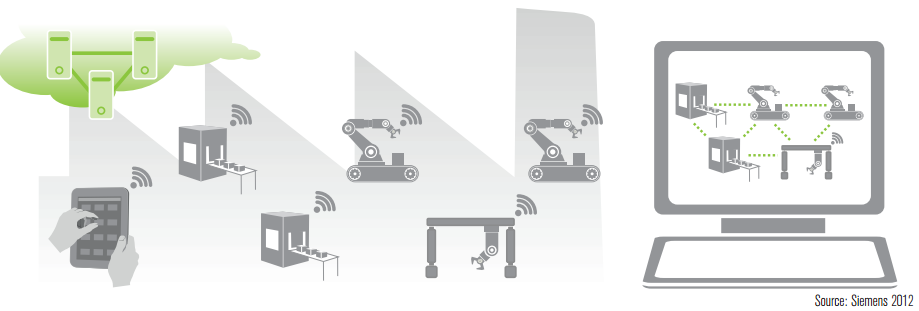

This involves creating flexible, reconfigurable, and decentralized manufacturing systems.

All levels of manufacturing operation should be networked:

- Sensors & actuators

- Production control

- Performance management

- Corporate planning

Design Principles

Although the working group’s final report was deliberately light on details, there has been subsequent work on the subject and a number of specific design principles can be inferred. In 2015, a group at the Technische Universität Dortmund reviewed academic and business publications on the subject and identified six primary design principles of Industry 4.0. The following is an excerpt from that paper:

Interoperability

Interoperability is a very important enabler of Industrie 4.0. In Industrie 4.0 companies, CPS (Cyber-Physical Systems) and humans are connected over the IoT (Internet of Things) and the IoS (Internet of Services). Standards will be a key success factor for communication between CPS of various manufacturers. The German Commission for Electrical, Electronic & Information Technologies of DIN and VDE has recognized this need and published the “German Standardization Roadmap” in 2013. In the context of the SmartFactory plant, interoperability means that all CPS within the plant (workpiece carriers, assembly station, and products) are able to communicate with each other “through open nets and semantic descriptions”

Virtualization

Virtualization means that CPS are able to monitor physical processes. These sensor data are linked to virtual plant models and simulation models. Thus, a virtual copy of the physical world is created. In the SmartFactory plant the virtual model includes the condition of all CPS. In case of failure a human can be notified. In addition, all necessary information, like next working steps or safety arrangements, are provided. Hereby, humans are supported in handling the rising technical complexity.

Decentralization

The rising demand for individual products makes it increasingly difficult to control systems centrally. Embedded computers enable CPS to make decisions on their own. Only in cases of failure tasks are delegated to a higher level. Nevertheless, for quality assurance and traceability it is necessary to keep track of the whole system at any time. In the context of the SmartFactory plant decentralization means that the RFID tags “tell” machines which working steps are necessary. Therefore, central planning and controlling is no longer needed.

Real-Time Capability

For organizational tasks it is necessary that data is collected and analyzed in real time. In the SmartFactory the status of the plant is permanently tracked and analyzed. Thus, the plant can react to the failure of a machine and reroute products to another machine.

Service Orientation

The services of companies, CPS, and humans are available over the IoS and can be utilized by other participants. They can be offered both internally and across company borders. The SmartFactory plant is based on a service oriented architecture. All CPS offer their functionalities as an encapsulated web service. As a result, the product specific process operation can be composed based on the customer specific requirements provided by the RFID tag.

Modularity

Modular systems are able to flexibly adapt to changing requirements by replacing or expanding individual modules. Therefore, modular systems can be easily adjusted in case of seasonal fluctuations or changed product characteristics. In the SmartFactory plant, new modules can be added using the Plug&Play principle. Based on standardized software and hardware interfaces, new modules are identified automatically and can be utilized immediately via the IoS.

Déjà vu all over again?

“Even though Industrie 4.0 is one of the most frequently discussed topics these days, I could not explain to my son what it really means” – Audi production site manager

The Industry 4.0 recommendations report describes a dual strategy for Germany: become both the leading users of Industry 4.0 concepts but also become the leading supplier of the necessary technologies and products. Much of the information found when searching for details on Industry 4.0 is either very high-level and theoretical in nature or it’s a particular vendor’s vision of how their products are “Industry 4.0 ready.”

While this can be confusing and frustrating for anyone looking for practical/implementation-specific information on the subject, it is important to understand that there is nothing really new or unique to Industry 4.0. It is simply the latest in a series of initiatives that are moving industry in the direction of increased integration:

- Digital manufacturing (1970s)

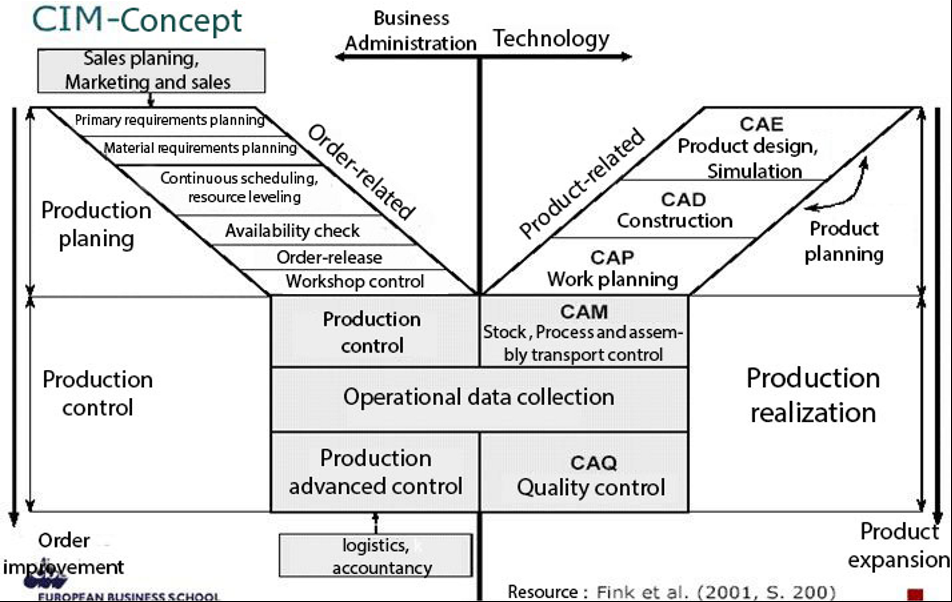

- Computer integrated manufacturing (CIM) (1990s)

- Digital Factory (~2000)

- Factory 2.0 (2005)

- Smart Factory (2007)

Industry 4.0 shares many of the concepts of Computer integrated manufacturing but emphasizes decentralized and largely autonomous systems with common data interfaces.

CIM was developed before the potential for web-based services was really understood. Along with the rise of the “Internet of Services”, there are several other recent but undeniable trends happening in manufacturing. A 2015 McKinsey report highlighted a few:

- Big data. An African gold mine found ways to capture more data from its sensors. New data showed some unsuspected fluctuations in oxygen levels during leaching, a key process. Fixing this increased yield by 3.7 percent, worth up to $20 million annually.

- Advanced analytics. Stronger analysis can dramatically improve product development. One automaker uses data from its online configurator together with purchasing data to identify options that customers are willing to pay a premium for. With this knowledge, it reduced the options on one model to just 13,000—three orders of magnitude fewer than its competitor, which offered 27,000,000. Development time and production costs fell dramatically; most companies can improve gross margin by 30 percent within 24 months.

- Human-machine interfaces. Logistics company Knapp AG developed a picking technology using augmented reality. Pickers wear a headset that presents vital information on a see-through display, helping them locate items more quickly and precisely. And with both hands free, they can build stronger and more efficient pallets, with fragile items safeguarded. An integrated camera captures serial and lot ID numbers for real-time stock tracking. Error rates are down by 40 percent, among many other benefits.

- Digital-to-physical transfer. Local Motors builds cars almost entirely through 3-D printing, with a design crowdsourced from an online community. It can build a new model from scratch in a year, far less than the industry average of six. Vauxhall and GM, among others, still bend a lot of metal, but also use 3-D printing and rapid prototyping to minimize their time to market.

Opportunities and Benefits of Industry 4.0 for Roll Forming Operations

Companies in roll forming-based industries have been working toward the design goals of Industry 4.0 and earlier initiatives for years. In most cases, these companies were unaware of how their efforts fit into any particular academic model; they were simply using technology to solve business problems.

Here are some of the most common types of projects support Industry 4.0 concepts:

Integration of all computerized production equipment

- Eliminate data islands! (humans shouldn’t have to convey information from one computerized system to another)

- ERP & MES systems

- Machine controls

- Packaging equipment

- Part marking equipment

- Bundle labeling printers

- Load scales

- Minimize paper

- Expand data interfaces between equipment to reduce or eliminate the need for production paperwork

- Use bar-code and RFID tags to track all material movements from receipt of coils to loading of finished goods on a truck. These identifiers can also be used to coordinate operations in multi-step production processes.

- Strive for real-time interfaces

- Continuous flow of data between all levels

- Eliminate large batch operations

- Manufacturing controls should pull data as needed rather than periodic push from above

Add data interfaces to outside companies

- Customers (internal & external)

- Electronic submission of job data (including custom part data)

- Demand estimates

- Real-time job completion status

- Material suppliers

- Coil shipment manifest

- Material certification data

- Put information where it can do the most good

- Use of low-cost consumer-grade LCDs, tablets, etc.

- Real-time display of current performance data at each machine/process

- Untether staff from desktops

Collect more data!

Data is cheap! Storage costs are quite low and cloud-hosted solutions minimize computing & storage burden on IT

You don’t know what information will be useful tomorrow – it’s better to collect more now and delete later rather than wish you had the data.

- Process inputs

- Production details/context

- Date, time, shift, machine, operator, product, material type, vendor, part length, etc.

- Process variables

- Actual material thickness (both sides if slit coil), camber, mill torque, roll stand pressure, welding current, stretch, etc.

- Resulting outputs

- Productivity

- Production rate

- Time running/halted + reasons for downtime or slowdowns

- Scrap generation + reasons

- Quality

- Automated In-line or off-line profile & length dimensional measurement systems

- Manual audits (enforced and recorded by machine controls)

- Productivity

- Production details/context

Develop good tools for analyzing data

- Correlation between production inputs and outputs

- Correlation coefficient useful when there are linear relationships

- Graphical analysis often helpful for spotting non-obvious relationships

- Performance metrics

- Short term for immediate feedback for operations staff

- Runtime %, scrap %, target %

- OEE can be misleading when there is high variability in changeover schedule.

- Long term for monitoring continuous improvement efforts

- OEE

- Short term for immediate feedback for operations staff

Primary Benefits: Operational Excellence + Improved Competitiveness

- Mistake-proofing

- Increased throughput

- Improved inventory accuracy

- Production flexibility

- Reduced scrap

- Improved part quality

- On-time deliveries

Implementation Challenges

- Reliability!

- Equipment and communications will fail – not if but when

- Designs need to be resilient and tolerant of such failures

- Approach similar to machine safety: no single failure should cause significant outage

- Security!

- IT departments have legitimate concerns about opening doors to corporate networks

- Lessons from Stuxnet (https://en.wikipedia.org/wiki/Stuxnet)

- Interoperability/data format compatibility

- Benefits from industry/gov push for standards

- Minimize custom programming

- Workforce availability and training

- Improved usability can minimize training needs, but still may be a difficult transition for many workers.

- Increased reliance on technical support staff

- Financial justification

- Every investment should be justified!

- Ideally there should also be a plan for auditing expected performance gains post-implementation

Financial Impact

When justifying investments in manufacturing technology, it’s important to consider your primary bottleneck. Is it sales or your roll forming machines? In other words, if you could produce X% more product, could you sell it at full or a discounted price?

If the answer is no, then sales is your bottleneck and you need to look at direct manufacturing costs for potential savings. The most common targets include:

- Unnecessary waste:

- Scrap, labor and shipping costs caused by mistakes or unreliable equipment

- Waste caused by machine or process design

- Labor (direct & indirect production staff)

If sales is not the bottleneck your opportunity costs may be much higher than your direct manufacturing costs. The potential increase in operating profit is often a matter of looking at the selling price of a product minus the material cost on a per foot basis. Labor should be considered as part of your overhead costs. If you can produce 10% more output with the existing staff and overhead, the extra footage times the margin per foot (selling price – material cost) is your potential improvement in operating profit.

Conclusion

Industry 4.0 represents an evolutionary step in an ongoing movement towards a higher level of manufacturing integration rather than a true revolution. Nonetheless, the concepts are valid and there is great potential for companies willing to pursue the vision that it sets forth. As with any investment in technology, it is critical that every project have a rational financial justification.

References

http://www.raeng.org.uk/publications/other/henning-kagerman-acatech-presentation

http://www.mckinsey.com/business-functions/operations/our-insights/manufacturings-next-act

https://www.bmbf.de/files/Umsetzungsempfehlungen_Industrie4_0.pdf

http://americanmachinist.com/automation/media-hype-or-new-era-manufacturing