-

Technical Support

-

- A Case for Computer Integrated Manufacturing (CIM)

- Basic Methods of Length Control

- Benefits of Computer Integrated Manufacturing (CIM) - Deutsch

- Coil Handling

- Continuous Improvement - Tube & Pipe Journal

- Continuous Improvement in Roll Forming

- Encoder Tracking and Mounting

- Improving Roll Forming Operations

- Part Marking

- Roll Forming and Industry 4.0

- Roll Forming: The Four Basic Machine Types

- Servo Control for Improving Roll Formed Production

-

-

XL200 Series Support

-

- Battery Replacement

- Calibrating the Touchscreen of an XL200 Controller

- Extending XL200 Controls with PLC Integration

- Solving Memory Loss and Computer Lockup Problems

- Using Product Codes for Machine Positioning in the XL200 Series Controller

- Using Setup Configurations in the XL200 Series Controller

- Using Tool Configurations in the XL200 Series Controller

- XL200 Direct Ethernet Communication with Eclipse Classic

-

- Bar Code Scanners

- Bar Code Scanners for Data Entry

- Boosted Dies

- Calculating Press Reaction

- Checking Press Consistency with Oscilloscopes

- DIP Switch Configuration

- Punch Programming on the XL200

- Sending Saved Parameters or Tool Libraries from Eclipse Classic to XL Controller

- Understanding the XL200 Part Queue

- Using Product Codes for Machine Positioning in the XL200 Series Controller

- Using Setup Configurations in the XL200 Series Controller

- Using the Stitching Feature

- Using Tool Configurations in the XL200 Series Controller

- XL200 Error Codes

- XL200 Parameters

-

- BOSS Shear

- Brake & Hump - XL200CLU

- Calculating Press Reaction

- Checking Press Consistency with Oscilloscopes

- Closed Loop Flying Die / Die Accelerator

- Closed Loop Stopping

- Coil End Point

- Extending XL200 Controls with PLC Integration

- Open Loop Flying Die

- Open Loop Stopping / Feed-to-Stop

- Tailout Sensor

-

Eclipse Support

-

- A Case for Computer Integrated Manufacturing (CIM)

- Benefits of Computer Integrated Manufacturing (CIM) - Deutsch

- Coil Inventory Management with CIM

- Improving Production Capacity with Computer Integrated Manufacturing (CIM)

- Mistakes Happen! CIM for Mistake Prevention in Roll Forming

- Roll Forming and Industry 4.0

- The Quality Gap

-

- Automatically Starting Eclipse Classic

- Cable Specifications for RS Communication

- Coil Validation

- Creating an Eclipse Classic Package File

- Deleting Done Orders in Eclipse Classic

- Eclipse Classic Hardware Requirements

- Eclipse Classic Permissions - XLSecurity.exe

- Eclipse Connections

- Eclipse Data Exchange Options

- Establishing Communication with Eclipse

- Implementing Scrap, Delay, and Employee Codes in Eclipse Classic

- Interfacing Eclipse to External Data Systems - Importing and Exporting

- Material Code Query

- Missing Snapshot or Dates for Reports in Eclipse Classic

- Order Downloading Options in Eclipse Classic

- Performing Eclipse Classic Automatic Backups

- Performing Eclipse Classic Manual Backups

- Preventative Maintenance Made Easy

- Replacing a Controller / Recovery from a Memory Clear

- Reporting from Archived Data

- Reporting from Archived Data

- Requesting Eclipse Classic Support

- Sending Saved Parameters or Tool Libraries from Eclipse Classic to XL Controller

- Using a Proxy Server

- VLINX ESR901 Converter Installation and Configuration

- Show all articles ( 10 ) Collapse Articles

-

Pathfinder Support

-

- Calibrating the Backgauge - Pathfinder v2

- Calibrating the Machine - Pathfinder v2

- Calibrating the Touchscreen - Pathfinder v2

- Cleaning Controller Screens

- Extracting the Pathfinder SDF from a 5XXX/6XXX Machine

- Installing TeamViewer

- Pathfinder PC Backup/Restore/Import Procedure - Pathfinder v2

- Pathfinder PC BIOS Configuration - 5X00

- Pathfinder PC BIOS Configuration - 6X00

- Solving Memory Loss and Computer Lockup Problems

- XL250BB Backup/Restore Function

-

- FoldGuard Alignment Guide

- FoldGuard Alignment Guide - LZS-2-FG

- FoldGuard Brochure

- FoldGuard Encoder Installation Manual 1-02

- FoldGuard Frequently Asked Questions (FAQ)

- FoldGuard Operation Manual

- FoldGuard System Installation Manual 1-06

- FoldGuard System Installation Manual 1-07

- Laser Distortion Causes and Solutions Manual 1-02

-

MP Series Support

-

- MP300 Series Controller Manual

- MP300CL Series Controller Manual

- MP325 Manual

- MP328 Gripper Manual

- MP328CL Gripper Manual

- MP338 Backgauge Manual

- MP338DH Dual Backgauge Manual

- MP342 Manual

- MP343 Manual

- MP350PFD Manual

- MP450S Installation Guide

- MP465 Installation Guide

- MP465 Operator Manual

- MP465N Operator Manual NTM

-

-

Pathfinder Edge Support

-

- Accessing Pathfinder Edge

- Installing TeamViewer

- Logging into Pathfinder Edge

- Pathfinder Edge - Profile Object Format

- Pathfinder Edge Published API

- Print an Approval or Production Sheet - Edge

- Understanding Settings - Edge

- Using Categories and Subcategories - Edge

- Using the Profile Editor - Edge

- Using the Profile Library - Edge

-

Eclipse Pro Support

- Alert: Eclipse-COMM may be offline

- Alert: Material code XXXXXXXX does not correspond to a known material

- Checking the Status of Eclipse Pro Services

- Connect to Eclipse Pro from a Network Connected Device

- Eclipse Pro Hardware Requirements

- Eclipse Pro Product Sheet

- Eclipse Pro Product Sheet - Spanish

- Eclipse Pro Release Notes

- Eclipse Pro Scheduler

- Eclipse Pro Wallboard Andon App Setup

- Error: "Duplicate material codes. MATERIAL =..."

- Machine Performance Standards

- Nucor Case Study

- Requesting Eclipse Pro Support

- Schedule Sync Table Definition

- Updating Eclipse Pro

- Show all articles ( 1 ) Collapse Articles

-

Accessories Support

-

- 4805-XX and 3805-XX Encoder Cable Comparison

- BRKT-2 Assembly STEP File

- Encoder 10-Turn Test

- Encoder Bracket BRKT-1 Dimensional Drawing

- Encoder Bracket BRKT-2 Assembly Dimensional Drawing

- Encoder Bracket BRKT-2 Dimensional Drawing

- Encoder Brochure

- Encoder Sell Sheet

- Encoder Splitter 6390 Electrical Block Diagram

- Encoder Splitter 6390 Sell Sheet

- Encoder Splitter 6390 Shell STEP File

- Encoder Splitter Module 6390 Guide

- Encoder STEP File

- Encoder Tracking and Mounting

- Encoder Wheel KMW Dimensional Drawing

- Encoder Wheel PMW Dimensional Drawing

- KMW-12 Knurled Encoder Wheel STEP File

- NXXXX Encoder Assembly STEP File

- Scrap Reduction Using Two Encoders

- Troubleshooting Encoder Alignment

- Show all articles ( 5 ) Collapse Articles

-

- Indraworks DS Tuning Procedure (Analog) for CSB02_1 Control Sections

- Indraworks DS Tuning Procedure (Analog) for HCS01_1E Cs Servo Drives

- IndraWorks DS Tuning Procedure (EtherCAT) for CSB02_1 Control Sections

- IndraWorks DS Tuning Procedure (EtherCAT) for HCS01_1 Drives

- Indraworks DS Tuning Procedure (SERCOS II) for CSB01.1 Control Sections

-

Legacy Product Support

-

- About the MP401

- Cleaning Controller Screens

- CMP1000 Reference Manual

- CMP11-10 Reference Manual

- CMP12 Reference Manual

- MP100 Reference Manual

- MP101 Reference Manual

- MP101 v2 Reference Manual

- MP103 Reference Manual

- MP103 v3 Reference Manual

- MP237 Reference Manual

- MP257 Reference Manual

- MP37 Reference Manual

- MP38 Reference Manual

- MP39 Reference Manual

- MP401 User Manual

- MP43 Reference Manual

- MP44 Reference Manual

- MP450 Installation Guide

- MP450 Operator Manual

- MP450S Installation and Technical Reference Manual

- MP450S Installation Guide

- MP450S Operator Manual

- MP450Z Operator Manual

- MP46 Reference Manual

- MP465N Operator Manual NTM

- MP54 Reference Manual

- MP55 Reference Manual

- MP550 Operator Manual

- MP56 Reference Manual

- MP57 Reference Manual

- Show all articles ( 16 ) Collapse Articles

-

Radius Parts and Stamping Mode

Radius profiles can be created with Pathfinder in two different ways, with Stamping Mode enabled or disabled. Stamping the profile is faster than individually clamping and bending each segment, but does not always yield the same results.

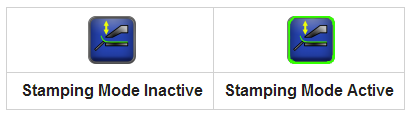

Stamping Mode is enabled using Parameter 703 – Allow Stamping Mode in Operator Preferences. After enabling Stamping Mode, Pathfinder must restart for the mode to become active. The Stamping Mode button will appear on the Status Bar if the Allow Stamping Mode parameter is set to YES. If Stamping Mode is active, the button will appear highlighted in green.

Note: When Stamping Mode is activated, all profiles with radius bends are run using the stamping mode.

A radius machine operation starts out the same as a normal bend by moving the backgauge to the correct starting Backgauge Position, and requiring the machine operator to fully close the clamping beam to clamp the profile. However, once he steps on the Bending Cycle Start foot pedal, one of two actions may occur depending on Pathfinder’s current Stamping Mode setting:

- With Stamping Mode disabled, the motion controller raises the bending beam to the incremental Bending Angle (including all overbend adjustments), then lowers the bending beam back to home. The clamping beam opens to the machine operation’s Minimum Opening Height, and the backgauge moves forward by the incremental backgauge step distance (determined by the radius Quality setting), just like a normal bend.

- With Stamping Mode enabled, the motion controller raises the bending beam to the incremental Bending Angle (including all overbend adjustments), then keeps it raised for all successive sub-steps. For each sub-step, the clamping beam opens to the machine operation’s Minimum Opening Height, and the backgauge moves forward by the incremental backgauge step distance, but the bending beam does not return to its home position until all sub-steps have been completed.

Note: When using Stamping Mode, if the Clamp rises above the Safety Stop, the bending beam will return to zero and Stamping Mode will not work as intended. You can adjust your Safety Stop in Parameter 317 – Safety Stop Height.

Once all sub-steps have been completed, the clamping beam opens to the programmed Clamp Open Position (or Parameter 312 – Minimum Opening Height, whichever is greater) to release the profile.